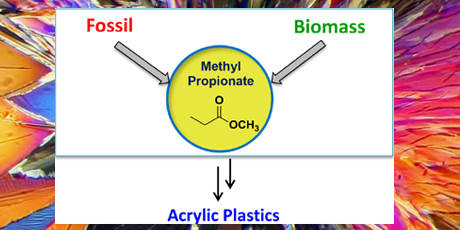

Green Routes to Acrylic Plastics

Novel ionic liquid catalysts can be applied to the synthesis of methyl propionate, which is an important precursor for production of acrylic plastic.

Methyl propionate (MeP) is an important chemical in the synthesis of acrylic plastics. Traditionally, MeP is produced from fossil crude oil, but it can also be produced from biomass. Thus, MeP can be part of the transition to renewable raw materials in the fine chemicals industry. The thesis investigates new routes for synthesis of MeP. If such routes prove more efficient than existing ones, they can be considered green, as they will yield more product relative to the amounts of raw material and energy used.

MeP is a methyl ester of propionic acid. It occurs naturally as a volatile component of kiwi fruit and strawberries. The main industrial application of MeP is as a precursor for the production of acrylic plastics. More specifically, MeP is a chemical platform for the synthesis of methyl methacrylate (MMA). MMA is further polymerized to give poly-methyl methacrylate (PMMA); a strong, durable and transparent plastic sold under the trade marks Perspex and Plexiglas.

In the fine chemicals industry MeP is synthesized in mainly three ways. These are methoxycarbonylation of ethylene, oxidative esterification of propanal, and Baeyer-Villager oxidation by enzymatic catalysis.

The project focused at new approaches to these processes. A suggested new approach is the use of ionic liquids as catalysts. An ionic liquid is defined as “a substance composed of two distinct ions that is liquid below 100 °C”. Application of Brønsted acid modified ionic liquids as acidic promotors and reaction media in methoxycarbonylation of ethylene to methyl propionate synthesis was investigated. Ionic liquid comprising liquid-liquid biphasic media encourages efficient methyl propionate separation and Pd-biphosphine complex catalyst recyclability.

Further, an advanced ionic liquid catalyst concept was investigated. The supported ionic liquid phase (SILP) catalyst technology was used for vapour phase continuous flow process for methyl propionate synthesis. SILP can be considered as “heterogenization of a homogeneouos catalyst”. The approach was shown to bring new opportunities for implementing homogeneous catalysts in industrial processes.

Finally, synthesis of methyl propionate from hydrogenolysis of methyl lactate derived from biomass was investigated. Various supported bimetallic catalysts were synthesized comprising precious and non-precious metals. The catalyst composition and its relationship with activity in the process were investigated.